...

2025-08-15 09:49

1828

...

2025-08-15 09:25

1701

...

2025-08-15 08:38

864

...

2025-08-15 08:21

1617

...

2025-08-15 08:19

1267

...

2025-08-15 08:12

593

...

2025-08-15 08:06

1238

...

2025-08-15 07:58

759

...

2025-08-15 07:51

2271

...

2025-08-15 07:39

2143

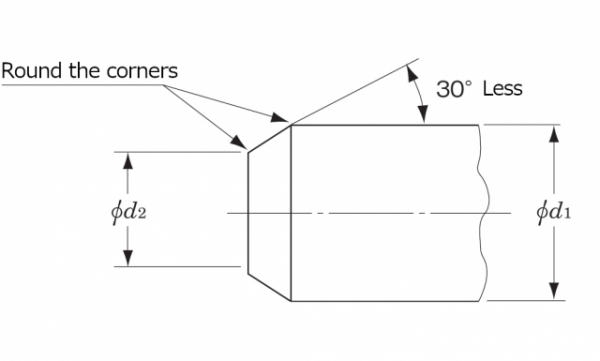

Figure 4: JTEKT oil seal features

1) Common seal types and their features

We would love to be of assistance to you in all your sealing inquiries

The perfect remedy for this is to use oil seal materials that are rated for the temperature of your application. Also, ensure that the elastomer is free from volatile constituents like waxes, plasticizers, etc.

- Secondly, OEM spark plugs contribute to improved fuel efficiency

oil tank gasket.

Do you still have specific questions about oil seals installation or want to know the right type for your application? Then please contact our specialists. They will be happy to help you with information and advice.

Note: For seal type codes, see Table 2.